Have you ever wondered why there are so many different sizes and blade shape of propeller? Does it make any difference to the average boat user which propeller is used? Well the answer to both questions is a definite yes. The propeller converts precious power into forward motion. If it is mismatched or damaged in any way its ability to do this will be severely affected and this will reduce your boat's performance. There is no point in having an engine in tiptop condition if you run it with the wrong propeller. So, with so many different types and sizes of propeller available how do you choose the correct one? Unfortunately, there isn't a simple answer. The following is only intended to be a rough guide to propellers, as it is beyond the scope of this article to cover every possibility, but you should begin to appreciate the different types and their applications. However, at the end of the day it is always wise to seek professional advice.

PROPELLER BASICS www.steeldevelopments.co.uk

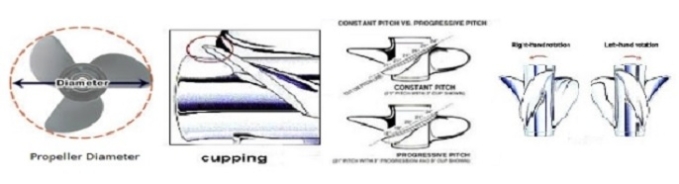

Firstly a propeller will have two sizes, diameter and pitch, and are usually measured in inches. For example 13" x 19". The first dimension, in our example 13" refers to diameter and the second 19" is the pitch. Diameter is simply the distance across a circle swept by the extreme tips of the propeller blades. Pitch is the theoretical distance travelled for one revolution of the propeller, in this case 19". However as water is not a solid substance this figure is less, due to slip. A propeller blade has a leading and trailing edge. The leading edge cuts into the water first. The trailing edge is the edge from which the water flows away. Many propellers have a slight upturn on the trailing edge, this is known as cupping. Cupping has the effect of reducing cavitation. Cavitation is commonly confused with bush failure, as the effects can be very similar, IE. Sudden rises in engine rev's and loss of speed. Cavitation is caused when the surface of the blades become covered in tiny vacuum bubbles. A smaller degree of cavitation will cause vibration and if left in this condition for long periods will cause "cavitation burns" which is where the vacuum bubbles implode with enough force to start sucking metal off the blade surface, obviously not a good idea. Severe cavitation can cause the propeller to "break away" completely thus causing the effect mentioned earlier of engine rev's suddenly rising. The reason for cavitation is using either damaged or heavily fouled blades or overloaded blades due to incorrect propeller type/size. E.g. Too high a pitch for the engine power / boat speed.

So knowing these basic facts how do you determine what size propeller you need? You may think that a propeller with a very high pitch will give the fastest speed, and to some degree this is true. However pitch is directly connected to engine rpm. The higher the pitch the less the engine will rev. So if your engine should rev to say 5,000 rpm but you can only achieve 3,000 rpm then the pitch is too high. If you lower the pitch so you can get 5,000 rpm you will actually achieve a faster top end speed than with a higher pitched propeller. The equation is simple, you must achieve maximum rpm. This equals maximum horsepower development and therefore optimum performance. Under certain circumstances you may want to fit a propeller that will enable you to gain more rev's. If you are using your boat for watersking or wakeboarding for example, a propeller with a lower pitch will give increased acceleration and bite at lower speeds, ideal for pulling up waterskiers etc. However you must be careful not to exceed the recommended maximum rpm of your engine. Generally when you use a boat for skiing you do not run flat out so this is not a problem. As a rule of thumb the higher the pitch, the faster the top end speed but the lower the rev's. The lower the pitch the faster the acceleration and the higher the rev's.

The next consideration is the number of blades. Surprisingly the most efficient number of blades is one. This is because the single blade has nothing to disturb the water flow ahead of it, but in practice this is not realistic as a single blade would be impossible to balance. The next most efficient is a two blade, but this can be impractical as generally you would require a propeller with a very large diameter to get enough blade area to generate sufficient thrust. For this reason most propellers have three blades. Some propellers have four or five blades (or even more in some cases). These propellers are useful for two reasons. Firstly they reduce vibration will give a much smoother ride. Secondly they increase acceleration for the same given pitch. This is why boat owners who want increased acceleration, turning abilities and to maintain planning at lower speeds for skiing will often choose a 4 or 5 bladed propeller. Similarly 4 or 5 bladed propellers are very good for cruisers who want relaxed and smoother cruising. All propellers are a compromise and the choice of a 4 or 5 bladed propeller will reduce top end speed as the drag caused by the propeller increases. The drag factor is one of the reasons why surface piercing propellers are very efficient. They are designed to run with the water line at hub level. This keeps the majority of the blade area clear of the water and this reduces drag to a minimum and propulsion at maximum. However they are not suited to many applications as they can take longer to get the boat on the plane and they can cause manoeuvring difficulties, as surface propellers are notorious for poor astern characteristics.

A propellers blade shape will affect its performance. Most outboard and sterndrive propellers are constant pitched across the entire high-pressure face. Some are progressively pitched. A progressive pitched propeller is less prone to cavitation and will give increased acceleration and general performance. This is because the leading edge will be a lower pitch so the water is picked up under less pressure. The water then flows along the blade surface increasing in pitch to the trailing edge where it is forced into a tighter thrust funnel and this gives higher efficiency. Some propeller have blade rake, rake is when the blades lean or slop either forward or aft as viewed from the side. Blades that slop aft have positive rake and this will give the effect of increased top end speed, but less acceleration and is generally designed to increase bow lift. Blade area has an effect on performance, propellers with relatively high blade areas will have reduced blade loading and therefore suffer less from cavitation. Blade shape also has an effect. Generally pointed blades, such as cleaver types, will give stern lift. Rounded high rake blade shapes generally give bow lift. Some propellers have vent holes or slots at the root of the back face of the blade. This introduces air from the exhaust to the propeller, which reduces cavitation. Since cavitation is air bubbles in vacuum the aeration from the exhaust gases helps prevent cavitation from occurring. This is called ventilation i.e. air introduced to the propeller blade. These propellers are generally constant pitched. The latest and most efficient propellers are progressive pitched. These are less prone to cavitation and therefore do not generally require vent holes or slots as the blade loading is significantly reduced.

Surprisingly the material the propeller is made from also affects performance. Most outboard and sterndrive propellers are made from aluminium. Fitting a stainless steel propeller will increase performance. The reason for this is simple. Stainless steel is a much stronger material than aluminium which enables the propeller to be manufactured with a thinner blade section. If the leading edge is thinner less air bubbles will be formed on impact and thus cavitation is reduced. A thinner blade is much more efficient that a thicker one. For racing applications the blade section can be thinned to such an extent that you could literally use the propeller to have a shave. For most applications such a thin blade section is not desirable as it is more prone to failure under stress. For the enthusiastic boat owner, simply changing from an aluminium propeller to a stainless steel one will give improved performance. For significant improvements try a stainless steel progressive pitched propeller with cupping.

For outboard and sterndrive propellers, diameter is related to pitch, Generally the lower the pitch the larger the diameter and vice versa. The reason for this is generally boats that require low pitches are slower and heavier and they need propellers with a larger diameter to give improved thrust. Faster lighter boats need less thrust to achieve planning speeds and therefore less diameter but larger pitches to give optimum performance.

In conclusion, when you decide on a propeller size you need to carefully consider how you intent to use your boat. Are you looking to tow skiers, or do you want out and out speed. The same propeller cannot deliver high speed and maximum acceleration. You can either go for a compromise, using and in between propeller. or have a selection, so you have the ability to change propeller according to boat loading and conditions. As it is always advisable to carry a spare propeller the latter is the best option. Once you have a propeller it can be "fine tuned" to your boat set up. It is possible to alter the pitch on your existing propeller up to a maximum of one inch or any variation in between, to gain or loose those extra revs. You must keep your propeller in good condition. If it suffers any damage, however minimal it may seem, it will severely affect performance. You should have your propeller professionally repaired and serviced. Trying to do a DIY job will probably cost you more in the long run and you may even render the propeller beyond repair. Any repair costs will easily be saved by reducing fuel consumption and keeping the propeller as efficient as possible. You can increase your boats performance significantly if you have the best propeller suited to your application. If you are unsure, or want advice on any propeller related questions do not hesitate to contact a propeller specialist. www.steeldevelopments.co.uk

Propeller Frequently Asked Questions www.steeldevelopments.co.uk

What do the measurements on my propeller mean?

On your propeller there will be some numbers stamped such as 14" x 12". The first number relates to the diameter, in our example 14". The diameter is determined by doubling the distance between the blade tip and the center of the hub. Diameter can also be looked at as the distance across a circle that the propeller would make when rotating. The second number 12" in our example, refers to the pitch. Pitch is the blade angle and also the 12" pitch indicates that in each propeller revolution the boat theoretically would advance 12" through the water. However as water is not a solid substance there is some slip approximately 10-30% which means that the actual advance is some what less. It may sometimes be difficult to find the size marked on a propeller and also some propellers may have their measurements given in the form of a code so if you are unsure what size your propeller is we can advise you.

How do I know if my propeller is left or right hand?

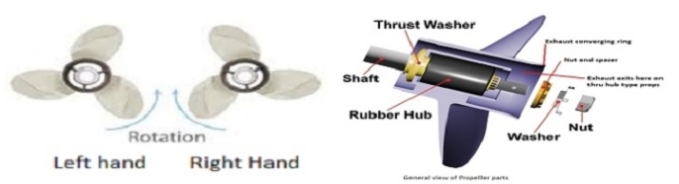

Propellers are either left or right handed. Left handed propellers rotate anti-clockwise as viewed from behind the boat looking towards the stern. Right hand propellers turn clockwise.

What does a propeller do?

A propeller not only pushes the boat along but also has a direct bearing on engine RPM. As most engines develop their maximum power at full rated RPM it is important to select a propeller that allows the engine to reach its full RPM. An example of this would be if your engine should have an RPM of 2500 but you can only get 2300 your propeller is too course in pitch. This can be altered by having the pitch reduced by one inch which will give you the needed 200 RPM to bring the engine to it's full rev's and efficiency and so reduce fuel costs. This RPM alteration is presuming a gear reduction of approximately 2:1. Pitch alteration is one of the many services that we can offer at a very reasonable cost, and you will probably save this money in reduced fuel costs and unnecessary wear to your engine. You should prop your boat so that you can achieve the maximum RPM from your engine. Once you have done this you will get the maximum horsepower from your engine and thus the best possible performance from your boat. Therefore Max. RPM = Max. Power = Max. Speed = Economy at cruise.

What is cavitation?

Cavitation can give the feeling of slip whilst the propeller is in use. It is actually bubbles in a partial vacuum caused by use of a damaged propeller, excessive propeller speed, loading or an incorrectly sized propeller being used. When a propeller moves through the water, the water is forced against the suction side of the propeller. The faster the blades cut through the water the more vacuum bubbles implode against the propeller. This implosion can happen with such force that the bubbles actually suck the metal right off the surface causing erosion or a "cavitation burn". Although it is not possible to repair cavitation burns it is possible to reduce cavitation and therefore reduce the possibility of further damage. This is done either by cupping the trailing edge of the propeller or ensuring that the propeller has the appropriate exhaust ring fitted if applicable, we can provide both of these services for you. You may also have the propeller blades thinned down as this reduces the high pressure build up on the blades.

What is ventilation?

Ventilation is the effect of external air or exhaust gases being made available to the propeller. The propeller blades during their operation have a pressure and suction side. When air is induced into the propellers working area, the suction or back side of the blade will accept any migrant air, thus causing loss of thrust, an increase in motor rpm, and poor performance

What are the most common causes of cavitation and ventilation?

The most common reasons for cavitation and ventilation are damaged and out of balance propellers If the bottom of the boat or the lower unit is fouled this will have an effect not only towards cavitation and ventilation but to the overall performance of the boat. The loss of a converging or exhaust ring from a thru-hub exhaust propeller will mean that the exhaust gases going through the propeller could either escape between the propeller and the gear casing if the converging ring is missing or not be properly deflected if the exhaust ring is missing. Too high a transom setting, a severe turn when in use, wrong motor angle and in general incorrect boat "set up" will all have an effect on the performance of your boat.

What is cupping?

Cupping is a slight up turn on the trailing edge of the propeller. Cupping will reduce cavitation , increase acceleration, reduce propeller vibration, and give better propeller "grip". Cupping is also the equivalent of increasing the pitch of the propeller by approximately one inch and this should therefore be taken into consideration. If you would like your propeller cupped this is one of the many services that we can provide.

What does the propeller "bush" do and can it fail?

Propeller bushes can be made from rubber or composite plastic and some propellers have torsion rods in their centers all give protection to the lower unit. All act like a shock absorber and decreases the stresses to which the lower unit and engine gears are subjected to in the cases of sudden engagement of drive or when the propeller hits an obstruction. Propeller bushes are usually reliable. If your bush is damaged you will get little drive from it probably only walking pace. However if your boat is going faster than this and you are experiencing "slip" this is probably not a faulty bush but an effect of cavitation or ventilation. If you do have a faulty propeller bush this can usually be replaced by a competent engineer.

Propeller Maintenance www.steeldevelopments.co.uk

Roughness, cavitation, corrosion and surface damage to a propeller reduces it's efficiency and hence raises fuel consumption and can cause other costly damage. A propeller is an important part of any boats equipment, so what do we recommend for propeller maintenance?

The Golden Rule

ALWAYS carry a spare propeller for use in emergencies, a spare propeller may mean the difference between getting your boat home or not. Carrying a spare propeller will mean that you can always use your boat, if you damage a prop you will have another to use. Also if you do damage a propeller you will have one to use whilst your other is being repaired. Propellers can be purchased at reasonable costs and it is more cost effective in the long run to carry a spare so you can use your boat whenever you wish. There is nothing worse than looking forward to using your boat and you can't because you have a damaged prop.

If your propeller is damaged

NEVER run a vessel for long periods with a damaged propeller as you may cause sever damage to your propeller by causing "cavitation burns" or bush failure. You may even damage your engine or stern gear. Apart from seeing obvious blade damage symptoms of a damaged propeller are vibration in use, loss of speed, apparent slipping (cavitation), loss of power, poor fuel economy

Grease the shaft

To avoid problems removing your propeller make sure you grease the propeller shaft with a water proof grease (such at 2-4-C grease) before you fit the prop and make this a routine part of your boats maintenance.

Painting Propellers

To avoid problems of sever corrosion, propellers and stern gear must NEVER be coated with standard anti-fouling or metal based paints. If you use an anti-fouling intended for use on stern gear and propellers you must ensure that you follow the manufacturers instructions to the letter which usually states that bare metal, particularly aluminium, must be primed prior to application. However, in our experience propellers that are painted with any type of anti fouling are more prone to electrolysis and we would therefore not recommend its use.

Anode Protection

Make sure you have an anode fitted to your vessel so you reduce the risk of your propeller and stern gear from getting electrolysis. Don't forget to check that the anode you select is suitable for the type of water you normally keep your boat in, i.e. salt water = zinc anodes or fresh water = magnesium anodes.

Stainless Steel Propellers

Some stainless steel propellers are prone to discoloration an corrosion. To help prevent this you can use products such as Quicksilver's Corrosion Guard which is a spray giving a clear protective film coating to the metal.

Propeller Servicing

To maintain the best possible performance from your boat you should have your propeller serviced at least once a year or certainly every time it is damaged. Roughness, cavitation, corrosion and surface damage to a propeller reduces it's efficiency and hence raises fuel consumption and can cause other costly damage. Watch out for changes in performance, vibration and loss of speed these are signals that your propeller needs to be serviced.

DIY Repairs

As a propeller is so important in achieving the best performance from your boat you should not try a "do it yourself" repair as this will probably cost you more in the long run and could result in the propeller being beyond repair, and it may cause other damage to your stern gear. It is very inexpensive to have your propeller professionally repaired and serviced. So why take the chance?.

Check out our web site www.steeldevelopments.co.uk for prices and further information

Article by Julie Hale

Contact: Steel Developments Propeller Repairs & Sales, 240 Merton Road, London, SW18 5JQ

Tel +44 (0) 20 8874 7059